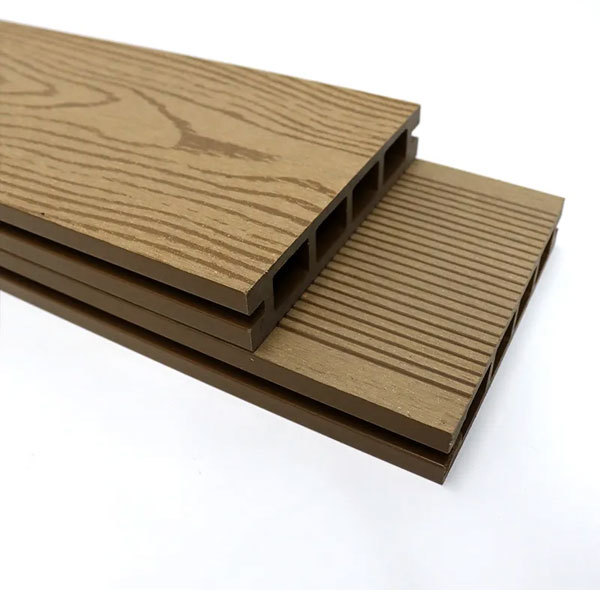

3D embossed square hole teak color

length: 2.2/2.4/2.8/4m or customized

Recommended for commercial decking projects.

Category:

Keywords:

We specialize in providing high-quality wood flooring that meets international standards to our global partners. Our products cover both residential and commercial applications, offering consistent quality and diverse styles to meet the market demands of various countries and regions.

Core Advantages

International Certification Guarantee: Our products have obtained multiple international certifications, including CE, FSC, and CARB. Our formaldehyde emissions are significantly lower than the EU E1 standard, ensuring compliance in mainstream markets such as Europe, the United States, and Southeast Asia.

-Materials and Craftsmanship: We utilize carefully selected solid wood imported from Southeast Asia (teak, oak, etc.) and a highly wear-resistant composite backing. We utilize a six-sided lacquer finish for exceptional moisture and deformation resistance, making them suitable for diverse climates, including wet and dry.

Customization: We offer customized dimensions (length, width, thickness), finishes (brushed, antique, matte), and packaging designs. We also offer neutral packaging and ODM services.

Main Product Lines

1. Solid Wood Flooring Series: Featuring natural wood grain, our products target the high-end home furnishing market and are suitable for European, American, Japanese, and Korean customers who value natural textures.

2. Laminate Flooring Series: A cost-effective choice with a surface wear resistance of AC4 or higher. Widely used in commercial applications such as apartments and hotels, it enjoys significant demand in the Middle East and South America.

3. SPC Interlocking Flooring Series: Formaldehyde-free, highly waterproof, and easy to install without glue, it has become a popular product category in cross-border e-commerce in recent years, ideal for small apartments and rental properties.

Partnership Support

Provide complete product test reports and customs declaration documents to assist customers with rapid customs clearance.

Flexible minimum order quantities (MOQs) allow for small trial orders, mitigating the risks of entering new markets.

A professional foreign trade team ensures efficient order fulfillment through comprehensive coordination and prompt response.

Whether you're expanding into the traditional building materials market or exploring new cross-border e-commerce channels, we offer highly adaptable products and professional services, making us your reliable wood flooring supplier.

Basic information

| model | ZY-W-001 | custom made | Customizable |

| surface treatment | Polishing/embossing/brushing | density | 1.2 kg~1.35 kg/cm3 |

| water absorption | less than 2% | working environment | burden40~60 degrees Celsius |

| Installation accessories | available | Warranty | more than five years |

| length | 2.2m/2.9m/3.6m or customized | Minimum Order Quantity | 200 sqm |

| delivery time | 15 days | main market | Europe |

| feature | Windproof/waterproof/UV-resistant | color | Gray, brown, coffee or customized |

| Fire rating | Category B | Sample supply | Yes |

| Sample preparation time | 2 working days | shipping packaging | Fumigation tray |

| Specification | 150*16mm | trademark | Slim and graceful |

| origin | China | HS code | 3918909000 |

| production capacity | 100000 square meters/month | feature | Windproof, waterproof, UV-resistant |

| shipping packaging | Pallet or bulk packaging | Specification | 145x21 mm |

Packaging and delivery

| Packing size | 32.00cm * 32.00cm * 22.00cm | ||

| Package gross weight | 5.000 kg | ||

Product Description

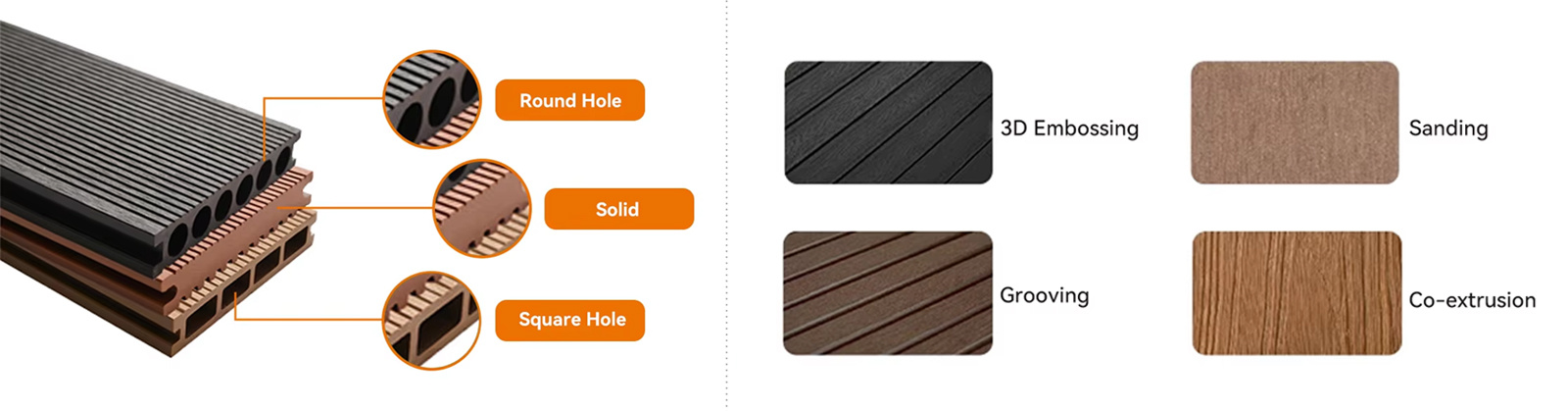

| 3D Wood Grain Anti-UV Exterior WPC Composite Wall Panel | |||

| Features: 1. Our composite wall cladding is made of recycled plastic (HDPE) and wood powder, plus harmless chemical additives such as UV stabilizers, light stabilizers, lubricants, shrink agents, etc., which can provide an extremely clean and professional finish to any wall panel. | |||

| 2. The anti-fading design is resistant to mildew and moisture, and is non-slip even in wet conditions. The rich color means that the wall cladding can be sanded like traditional wood while retaining its original color. | |||

| 3. Adjustable profile, adjustable length, adjustable color, adjustable surface treatment | |||

| 4. Our WPC wall cladding surface is equipped with treads, providing a variety of beautiful, sturdy non-slip surface options. The vivid wood grain appearance makes it more natural to look and touch. The board has a self-cleaning and mildew-proof structure, which requires almost no maintenance. | |||

Product information

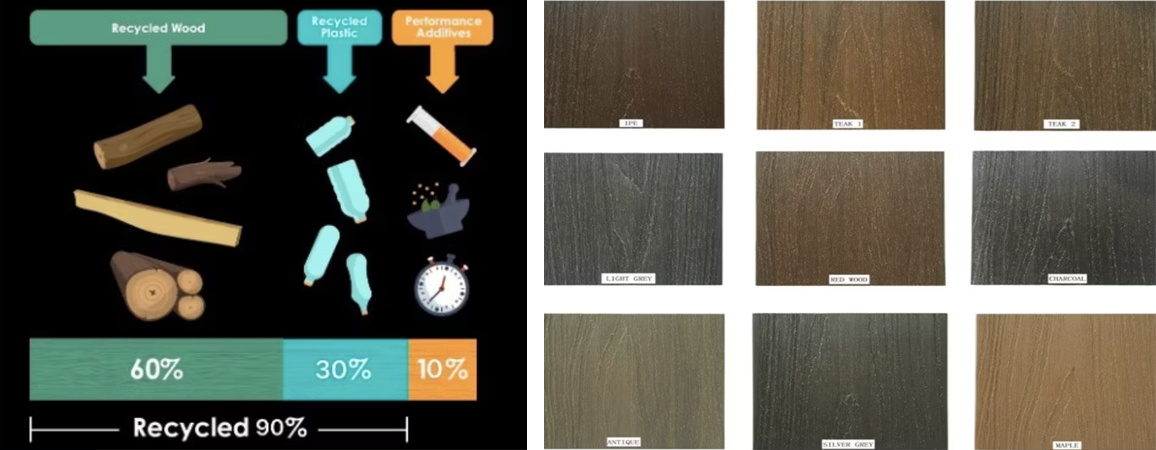

| Material Composition | 60% Wood + 30% High-Density Polyethylene + 10% Additives | Name | Co-extruded Fence Panel |

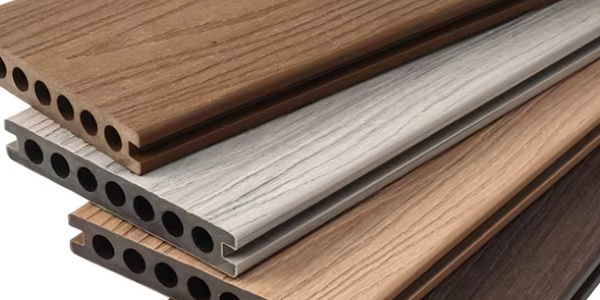

| Product Description | Hollow (Square/Round Hole Structure) or Solid | Item | Z-SB03 |

| Surface Treatment | Grinding, Embossing, Brushing, Smoothing | WPC Components | 30% HDPE + 65% Wood Fiber + 5% Additives |

| Product Surface Treatment | Online Embossing/Co-Extrusion/Classic | HS Code | 3918909000 |

| Available Lengths | 2.2m/2.9m/3.6m or Customized | Metal Fittings | Anodized Aluminum |

| Standard Sizes | 161x20mm | Delivery Time | A 20-foot box takes approximately 15-20 days |

| Popular Colors | Teak, Gray, Brown, Coffee | Payment | 30% deposit, the remainder due before delivery |

| Approximate Loading Quantity | 800-1000 square meters/1x20-foot container | Maintenance | Reduced Maintenance |

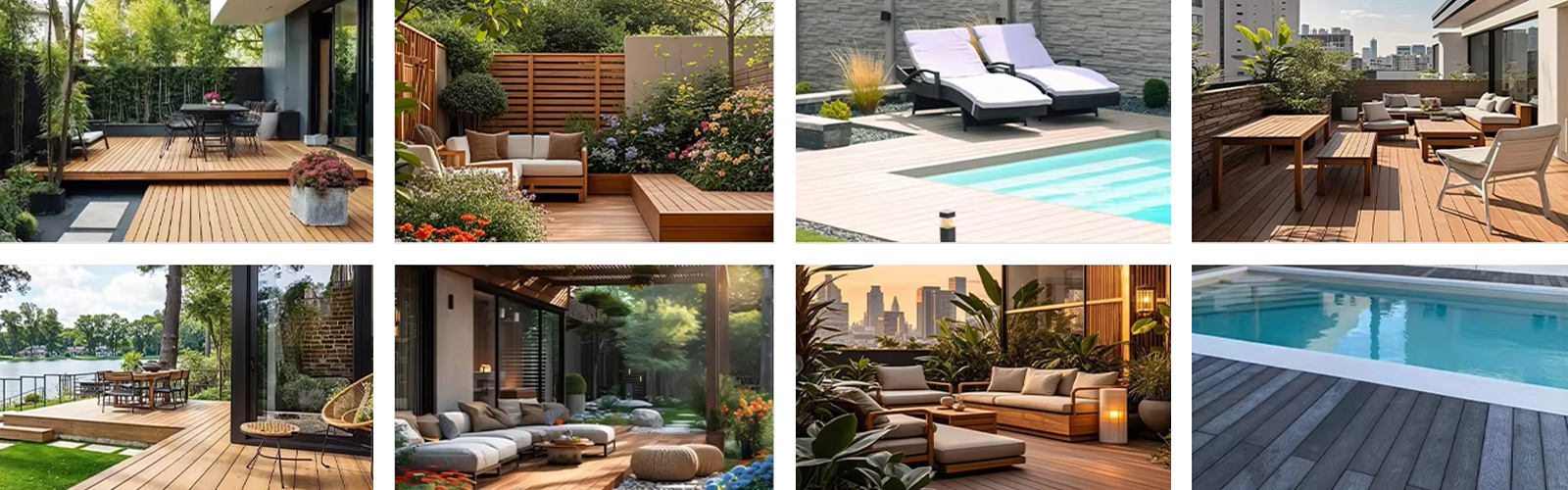

| Applications | Commercial or Personal, Home and Garden, Landscaping | Recycling | 100% Recyclable |

| Advantages of Wood | Long-lasting, Eco-friendly, Recyclable | Package | Pallet or bulk packaging |

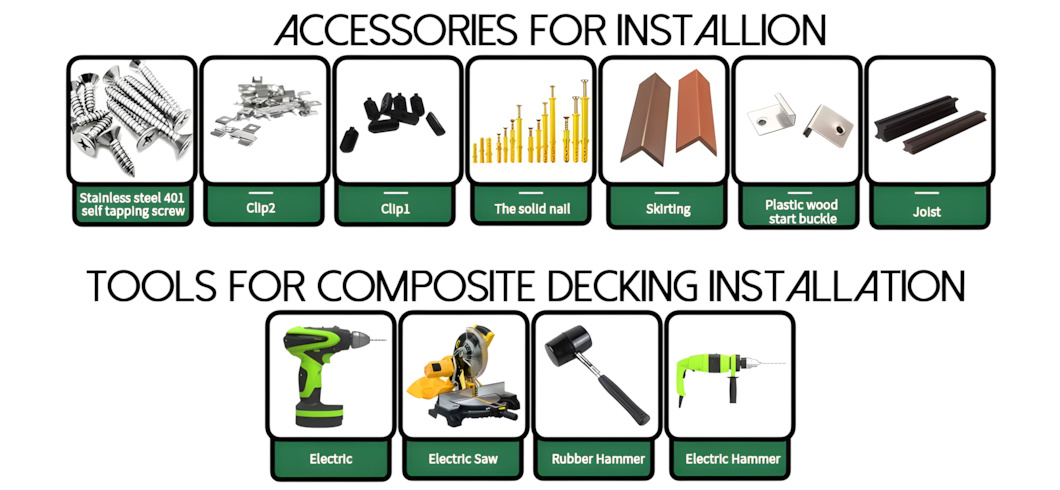

Wpc floor

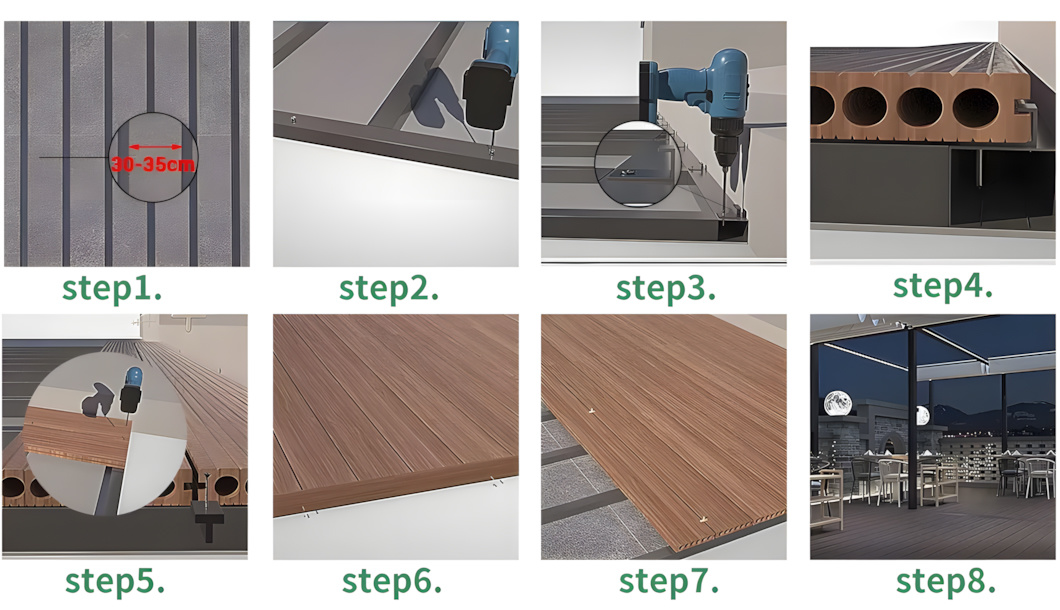

Installation steps

| Step 1, lay the keels one by one, ensuring that the distance between the keels is about 30-35cm. | ||||

| Step 2, Make holes on the keel, and screw the solid nails into the holes. | ||||

| Step 3, Fix the starting buckle on the edge of the keel,drive in the screws,and after fixing. | ||||

| Step 4, Start laying the plastic wood floor. Place the first floor horizontally and perpendicularly to the keel, and the initial buckle is clamped in the groove of the floor to fix one side of the first plastic wood floor. | ||||

| Step 5, Lay the second row of floors, insert the plastic buckle into the groove between the two floors, move it to the middle of the keel, insert the correspondina number of fasteners according to the number of keels and use a pistol drill to drive the screws into the fasteners and fix the keel | ||||

| Step 6, And soon for the floor behind. | ||||

| Step 7, When the last piece of floor is fixed on the keel with screws diagonally, and finally the floor is nailed to seal the edge, it is done. |

Our factory

What colors are available?

SUCCESS STORIES

FACTORY APPEARANCE

We have more than 10 years of experience

Xinxuan New Materials Co., Ltd. is a leading supplier with over 10 years of experience in manufacturing durable, high-performance and cost-effective composite wood products. We help companies of all sizes unlock the potential of composite wood products, and our customer base covers enterprises in industries such as industrial, construction, railway, transportation, landscaping, marine and leisure. We believe the following factors make us a qualified and satisfying supplier for our customers:

PRODUCT ADVANTAGES

Fundamentally solve the problems of water absorption, decay, expansion, deformation and so on in humid environment.

Anti-insect and anti-termite, effectively eliminate pests and extend service life.

Highly environmentally friendly, pollution-free and recyclable.

No cracking, no expansion, no deformation, maintenance-free, easy to clean, saving later maintenance costs.

APPLICATION CASES

CASE STUDY

CASE STUDY

CASE STUDY

CASE STUDY

CASE STUDY

CASE STUDY

PACKAGING AND DELIVERY

FAQ

How can we guarantee quality?

What services can we provide?

Accepted payment currencies: USD, EUR, JPY, RMB;

Accepted payment methods: T/T,L/C,D/P T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash;

Why should you buy from us not from other suppliers?

Is engineered wood flooring a good, environmentally friendly product to use?

Can I install Solid Wood Floor by DIY?

Our flooring comes with easy to follow instructions. Standard tool knowledge and common sense would naturally help.

Is engineered wood flooring a good, environmentally friendly product to use?

相关产品

RELATED PRODUCTS

CUSTOMIZED SOLUTIONS

Choose the color and pattern you need and we will provide you with free samples.

If you have any suggestions for our company or demand for our products, please be sure to contact us, thank you very much for your support and attention to us all the time!

For any questions you may have about composite wood products, we can provide you with professional advice and solutions.

Add : Environmental Protection Industrial Park, Xianghe County, Langfang City, Hebei Province

GET A FREE QUOTE

Leave your contact information and we will contact you during working hours.

Copyright : Xinxuan New Materials Co., Ltd. Powerby : CEGLOBAL SEO BUSINESS LICENSE PRIVACY POLICY